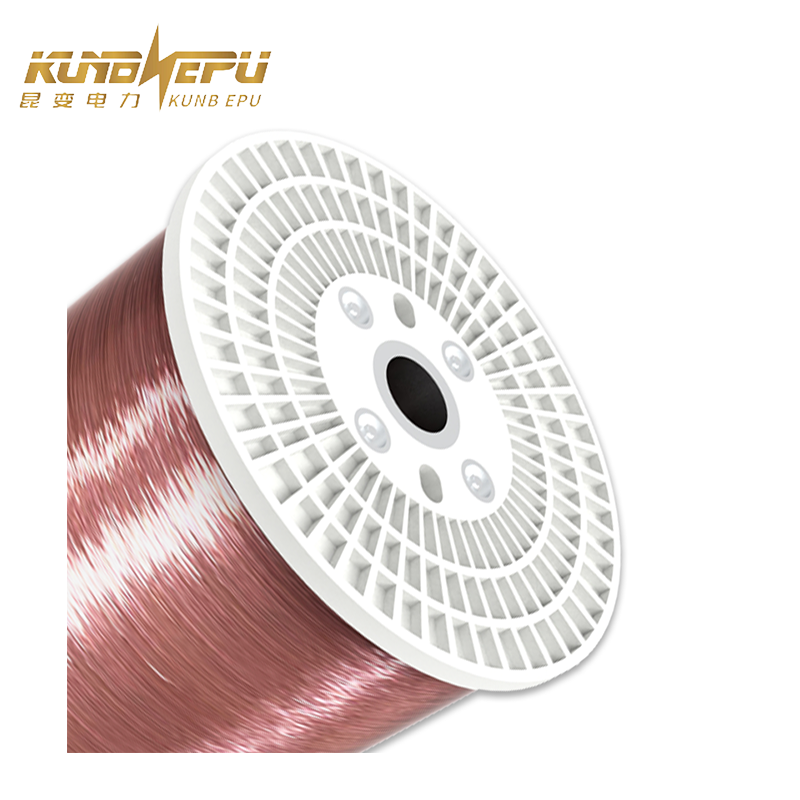

Enameled wire for inductors is crafted to meet the unique electromagnetic demands of inductor components. Inductors rely on the wire's ability to generate and store magnetic fields when an electric current passes through. Thus, the electrical conductivity of the wire core and the quality of the enamel insulation are of prime importance. The enamel coating provides a stable electrical separation between coil turns, preventing electrical leakage and optimizing the inductor's performance. A smooth and consistent enamel layer reduces friction during the winding process, enabling precise coil construction with accurate turn - to - turn spacing, which is vital for achieving the desired inductance value. In high - frequency applications, enameled wire for inductors often features materials with low dielectric losses to minimize energy dissipation within the inductor. Additionally, the wire must possess sufficient mechanical flexibility to conform to complex winding geometries while maintaining insulation integrity over time, ensuring the inductor's reliability in electrical circuits.

Copyright © 2024 by Kunbian Power Equipment (Shandong) Co., Ltd.