Understanding Three Phase Transformers in Industrial Systems

Core Principles of Three Phase Transformer Operation

Three phase transformers operate based on electromagnetic induction principles, which are integral to transforming electrical energy across voltage levels in industrial settings. This process hinges on alternating current (AC) to create magnetic fields, enabling efficient energy conversion without loss. By balancing loads strategically, three phase transformers ensure optimal power delivery across the grid. The phase relationships in three phase systems, as opposed to single phase systems, yield improved power quality and efficiency. According to industry reports, such advantages facilitate smoother industrial operations and heightened system reliability.

Key Components: Windings, Core Materials, and Cooling Systems

Windings, often made of copper or aluminum, are crucial components in three phase transformers. These materials influence the transformer's performance by conducting electrical currents with minimal loss. Core materials, including silicon steel and amorphous steel, play a vital role in minimizing core losses and optimizing the efficiency of the transformer. Cooling systems such as oil cooling and air cooling are employed to maintain operational integrity, ensuring the transformer remains effective even under heavy load conditions. Understanding these components helps in selecting the right transformer for specific industrial applications, thereby enhancing sustainability and performance.

Three Phase vs. Single Phase Transformers Compared

Power Efficiency Advantages for Industrial Loads

Three phase transformers excel in handling larger industrial loads due to their superior power efficiency compared to single-phase transformers. Scientific data suggests that three-phase systems are inherently more stable as they distribute power more evenly, reducing overall energy losses and maintaining consistent performance. A significant advantage of three-phase systems is their lower harmonic distortion, which enhances operational stability in industrial settings. Industries such as manufacturing and aerospace benefit greatly from three-phase systems, as these transformers provide the necessary robustness to handle complex machinery and heavy-duty equipment. For instance, the energy savings from using three-phase transformers in such industries can lead to reduced operational costs and improved power quality.

Cost-Benefits in Material and Energy Savings

Implementing three-phase transformers offers substantial cost benefits over single-phase transformers, both initially and in the long term. Although three-phase transformers might have a higher upfront cost, their efficiency in power distribution and reduced energy losses lower the total cost of ownership. By using optimized designs and materials, such as amorphous metal cores, they also result in significant material savings and longer lifespan, aligning with sustainability goals. Recent case studies from the manufacturing sector highlight a marked return on investment (ROI) for businesses transitioning to three-phase systems. These studies illustrate that the early investment is quickly offset by the energy savings and decreased maintenance requirements, reinforcing the economic viability of three-phase transformers in various industrial applications.

Three Phase Transformer Types and Configurations

Common Industrial Types: Step-Up/Down and Isolation Transformers

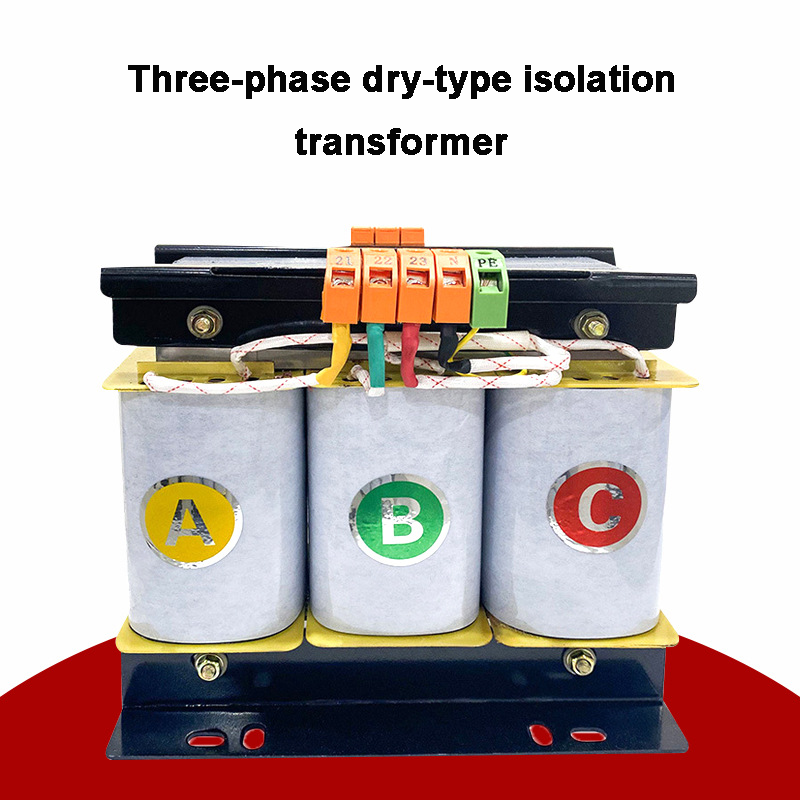

In industrial applications, step-up and step-down transformers play a vital role in managing voltage variations effectively. Step-up transformers increase voltage levels, which is essential for long-distance transmission of electrical power, reducing energy loss. Conversely, step-down transformers decrease voltage levels, making them suitable for distributing electricity safely to homes and businesses. Isolation transformers, on the other hand, are critical in providing electrical separation between circuits, enhancing safety and reducing noise in sensitive equipment. These transformers are particularly useful in industries where equipment protection and noise reduction are pivotal, such as in telecommunications and medical facilities, ensuring stable and safe operations.

Connection Methods: Star-Delta Configurations Explained

The star (Y) and delta (Δ) connection methods in three phase transformers are instrumental in achieving load balancing and efficient power distribution. Star connections provide a neutral point, ideal for managing long-distance transmission by reducing voltage stress on insulation. This configuration is commonly applied in scenarios where voltage regulation is crucial. Delta connections, however, form a closed-loop triangle, supporting high current loads and minimizing third-harmonic currents, which is beneficial in industrial settings. Many electric utilities employ these configurations depending on their specific energy distribution needs. For example, a star-delta configuration is frequently used in motor starting applications, showcasing its versatility in real-world applications.

Industrial Applications Across Sectors

Renewable Energy Integration: Solar/Wind Farm Usage

Three phase transformers are increasingly pivotal in integrating renewable energy sources like solar and wind farms. These transformers manage the variable power outputs typical of renewable sources, which helps enhance grid stability. By converting the fluctuating voltages from solar panels or wind turbines into a more stable power supply, they ensure consistent power delivery to the grid. According to recent statistics, the global adoption of renewable energy is growing steadily, with three phase transformers being instrumental in optimizing energy distribution. In 2022, renewable energy accounted for about 29% of global electricity generation, and the demand for robust transformer solutions is poised to increase as countries strive to reach their sustainable energy goals.

Mission-Critical Environments: Data Centers and Manufacturing

Three phase transformers play a crucial role in powering data centers and high-tech manufacturing environments, where reliability is paramount. These transformers ensure uninterrupted power supply, contributing to redundancy and fault tolerance essential in mission-critical operations. Experts highlight that the reliability standards in data centers require a high level of energy assurance, often achieved through the robust infrastructure provided by three phase transformers. For instance, the Uptime Institute's data indicates that power outages remain a top concern for data center operators, further underscoring the need for reliable power solutions that these transformers supply.

Supporting Infrastructure: EV Charging and Medical Facilities

Three phase transformers are also vital in supporting infrastructure such as electric vehicle (EV) charging stations and medical facilities. In EV charging stations, these transformers provide the necessary power efficiently and allow for scalability as more charging points are added. Studies show that the rise in EV adoption rates necessitates infrastructure capable of handling increased energy demands, where three phase transformers are indispensable. In medical facilities, the importance is even more pronounced as transformer reliability can directly impact patient safety, ensuring that critical medical devices remain operational. According to healthcare energy consumption analyses, maintaining uninterrupted power is non-negotiable, and the role of three phase transformers becomes crucial within this context.

Efficiency and Future Trends

Managing Copper and Core Losses in Heavy-Duty Operations

Reducing copper and core losses in three phase transformers is vital for enhancing operational efficiency and minimizing costs. Copper losses occur due to resistance in the windings, particularly during high-load conditions, while core losses are attributed to hysteresis and eddy currents within the core material. Innovations such as using high-quality core materials like amorphous metals can significantly cut down these losses. For instance, the application of silicon steel and advanced cooling systems not only improves overall performance but also aids in long-term cost reduction. Experts in the field emphasize that effective management of these losses is critical in the cost reduction efforts of industries reliant on heavy-duty power systems.

Smart Grid Compatibility and Sustainability Innovations

Smart grid technology is paving the way for enhanced energy management, with three phase transformers playing an integral role in these advancements. Their compatibility with smart grids allows for improved monitoring and control, facilitating better energy distribution and efficiency. Sustainability innovations in transformer design are emerging, focusing on reducing environmental impact while boosting energy efficiency. For example, recent grid renovations highlight how implementing smart transformers has decreased outage frequency and improved power quality in urban areas. This transformation underlines the growing importance of incorporating efficient and sustainable technologies in grid infrastructures to meet future energy needs.

Table of Contents

-

Understanding Three Phase Transformers in Industrial Systems

- Core Principles of Three Phase Transformer Operation

- Key Components: Windings, Core Materials, and Cooling Systems

- Three Phase vs. Single Phase Transformers Compared

- Power Efficiency Advantages for Industrial Loads

- Cost-Benefits in Material and Energy Savings

- Three Phase Transformer Types and Configurations

- Common Industrial Types: Step-Up/Down and Isolation Transformers

- Connection Methods: Star-Delta Configurations Explained

- Industrial Applications Across Sectors

- Renewable Energy Integration: Solar/Wind Farm Usage

- Mission-Critical Environments: Data Centers and Manufacturing

- Supporting Infrastructure: EV Charging and Medical Facilities

- Efficiency and Future Trends

- Managing Copper and Core Losses in Heavy-Duty Operations

- Smart Grid Compatibility and Sustainability Innovations