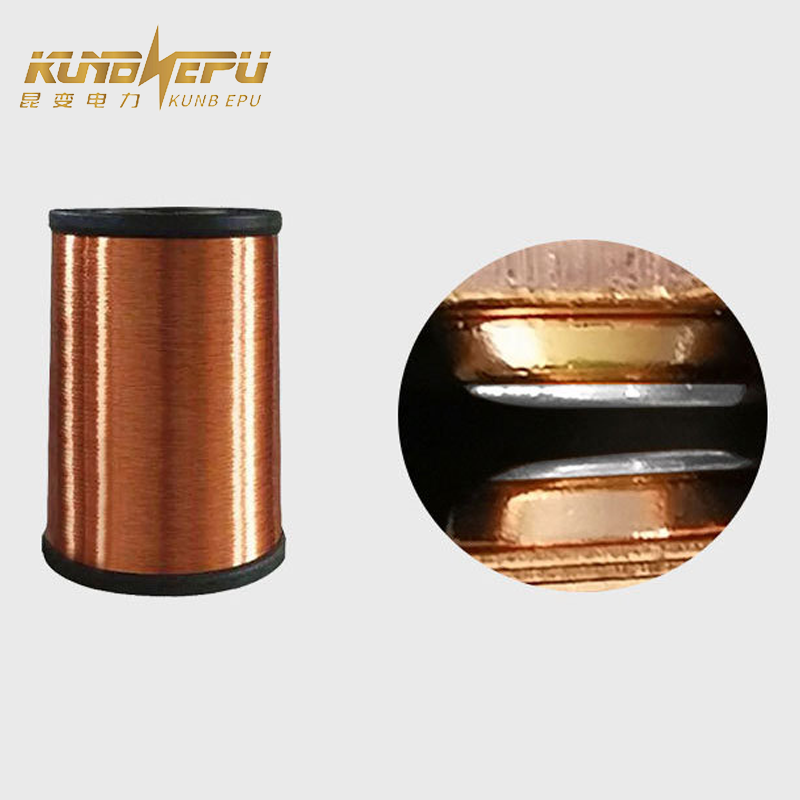

Enameled wire for winding coils is designed with specific characteristics to facilitate the creation of high - performance coils across a wide range of electrical and electronic applications. The key features of this wire lie in its insulation and physical properties. The enamel insulation coating provides a smooth surface, reducing friction during the winding process and enabling the formation of tightly packed coils with consistent turn - to - turn spacing. This is crucial for optimizing the electromagnetic performance of the coil, whether it is used in transformers, inductors, or electric motors. The insulation must have high electrical resistance to prevent short - circuits between adjacent turns, especially when the coil is subjected to high - voltage or high - current conditions. Enameled wire for winding coils also offers good mechanical flexibility, allowing it to be wound into complex shapes and sizes without breaking or damaging the insulation. Advanced manufacturing techniques ensure the wire has a uniform diameter and a high - quality enamel coating, contributing to the overall reliability and efficiency of the coils it is used in.

Copyright © 2024 by Kunbian Power Equipment (Shandong) Co., Ltd.