Understanding the Role of Grounding Rods in Lightning Protection Systems

Function and Importance of Grounding in Lightning Protection Systems

Lightning protection systems really depend on grounding rods to channel those massive voltage spikes from thunderstorms down into the ground where they belong. When buildings aren't properly grounded, we're talking about electrical surges that hit over 100 million volts, which can wreck structures and mess up all sorts of equipment. According to data from NFPA back in 2023, around six out of ten lightning damage incidents actually stem from poor grounding practices. The whole point of these rods is to create what engineers call a "low resistance path" so the dangerous energy doesn't build up inside walls or wiring. This simple concept saves countless properties each year from becoming collateral damage during storms.

How Grounding Rods Safely Dissipate Lightning Energy into the Earth

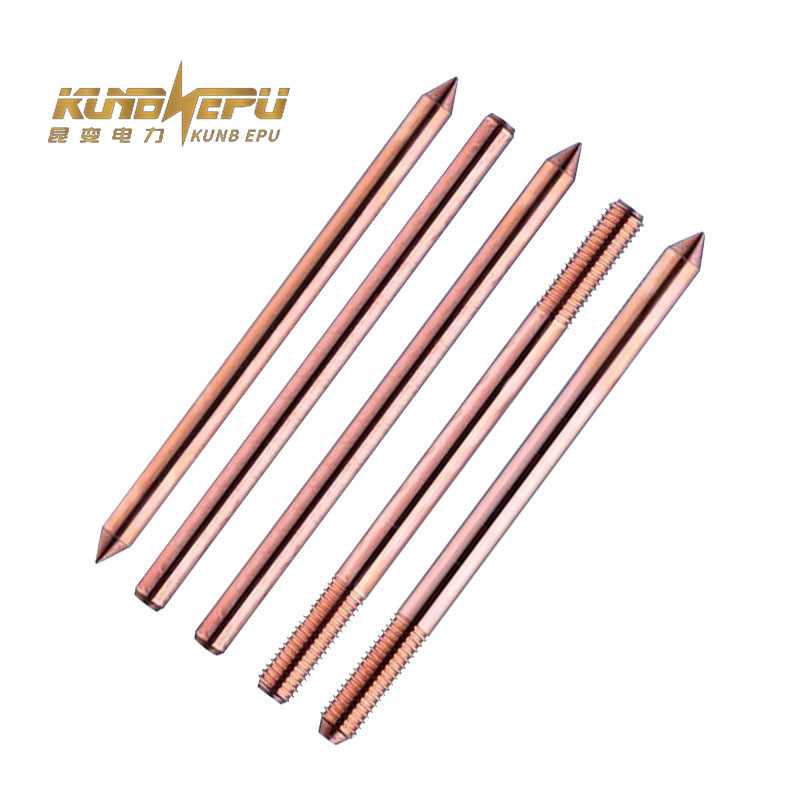

When lightning hits, grounding rods usually constructed from copper or copper covered steel channel electrical current down into the earth's conductive layers. A standard 8 foot rod works pretty well too, cutting soil resistance around 70 percent according to IEEE research from last year. The effectiveness gets even better when multiple rods are connected together as part of a network system. What happens next is pretty impressive actually the whole setup cancels out those dangerous voltage differences within just a fraction of a second, which helps prevent things like unexpected side flashes or dangerous step voltages that could harm people nearby.

Integration of Grounding Rods with Air Terminals, Conductors, and Bonding Systems

To get the best results from grounding rods, they need to work together with air terminals, down conductors, and bonding systems across the property. According to NFPA 780 standards, commercial buildings should have interconnected grounding systems that keep resistance at or below 20 ohms throughout the structure. When metal parts like pipes and heating systems aren't properly bonded to the main grounding grid, dangerous arcing can occur. These sparks are actually behind about one third of all indirect lightning fires according to UL Solutions research from last year. That's why proper bonding isn't just a technical requirement but a real safety concern for any facility owner.

Copper vs. Aluminum Grounding Rods: Corrosion Resistance and Conductivity

What material gets chosen makes all the difference when it comes to how well something performs and how long it lasts. Take copper for instance it conducts electricity much better than aluminum does, around 96% efficiency versus just 61% from aluminum. Sure, aluminum costs about 45% less upfront, but there's a catch. It tends to rust away pretty fast when exposed to harsh conditions. This becomes especially noticeable near coastlines where salt air eats into materials. Copper rods typically stick around three times longer in these spots. Still worth noting though, if someone takes the time to check the soil quality and implement some corrosion protection measures, aluminum can actually hold out for about 15 years on average. Makes sense why some folks go with aluminum despite its shortcomings when money is tight for their project.

Solid Copper vs. Copper-Clad Steel: Cost, Performance, and Longevity

Copper clad steel takes a strong steel core and wraps it with nearly pure copper coating at around 99.9%. This combination gives about 80% of what solid copper can do when it comes to conducting electricity, but costs roughly 40% less. Looking at data from the 2023 Grounding Material Efficiency Report shows that these copper clad systems keep their resistance below 5 ohms for approximately 25 to 30 years. Solid copper lasts longer though, maintaining similar resistance levels for about 35 to 40 years. When looking at typical applications where grounding needs stay under 10 ohms, copper clad steel usually provides the sweet spot between spending money and getting good results. However many important infrastructure projects still go with solid copper despite the extra expense because sometimes reliability matters more than budget considerations.

Grounding Rod Material Comparison

| Material | Corrosion Resistance | Conductivity (IACS) | Cost per Rod | Longevity (Years) |

|---|---|---|---|---|

| Solid Copper | Excellent | 100% | $120 | 35-40 |

| Copper-Clad Steel | Very Good | 80% | $70 | 25-30 |

| Galvanized Steel | Moderate | 10% | $40 | 12-18 |

Importance of UL-Listed Materials and Quality Certification

Grounding rods that carry the UL listing meet the necessary requirements for NFPA 780, specifically the 25-mil copper thickness standard, along with ASTM B3, B33, and B947 specifications. When looking at non-certified alternatives, they tend to perform poorly during UL 96A surge tests according to independent assessments. These uncertified products actually fail these tests about 58% more often than certified ones, which naturally raises concerns about potential system failures down the road. There's another issue worth mentioning too: counterfeit grounding rods that have less than 20 mils of copper coating contribute to around 23% of early failures seen in industrial environments. For anyone working on installations, it really pays off to check those mill test reports and confirm those UL markings are genuine before proceeding with any work.

Assessing Soil Conditions to Optimize Grounding Rod Effectiveness

Measuring Soil Resistivity for Effective Grounding System Design

When we talk about soil resistivity measured in ohm meters, what we're really looking at is how well electricity flows through the ground which affects grounding systems. The four point method according to IEEE standard 81-2012 gives pretty good readings since it spots differences between different layers of soil. Most clay soils sit somewhere between 10 and 100 ohm meters because they hold onto water better. Sandy or rocky areas though? Those often jump above 1000 ohm meters easily. And here's something important nobody mentions much seasonally changing moisture levels can slash resistivity values by as much as 80 percent. That means anyone serious about getting accurate results needs to do tests throughout all seasons if they want their grounding system to work properly over time.

Impact of Soil Type—Clay, Sand, and Rock—on Grounding Performance

Soil composition plays a decisive role in grounding effectiveness:

- Clay-rich soils naturally conduct current well due to moisture and mineral content.

- Sandy soils have high resistivity and often require deeper rod placement or chemical backfills like bentonite.

- Rocky terrain may necessitate ground enhancement materials or radial grounding systems to meet NEC Article 250’s 25-ohm threshold for residential installations.

Adapting Grounding Rod Installation Depth and Configuration to Soil Conditions

In high-resistivity soils (>500 ohm-meters), best practices include:

- Installing rods 8–10 feet deep (vs. standard 6–8 feet) to reach more conductive layers

- Spacing rods twice their length apart to avoid overlapping resistance zones

- Using UL-listed copper-clad steel rods in corrosive environments

NFPA 780 recommends up to 30% more rods in arid regions to compensate for poor soil conductivity.

Ensuring Compliance with Lightning Protection and Grounding Standards

NFPA 780 and UL 96A: Key Standards for Grounding System Design and Installation

Following NFPA 780 and UL 96A guidelines isn't just recommended but absolutely necessary when it comes to protecting buildings from lightning damage. The standards call for grounding rods made of copper or copper clad steel because these materials stand up well to both electrical conductivity needs and environmental wear over time. According to NFPA 780, most structures need their ground resistance kept below 25 ohms at maximum. Meanwhile UL 96A gets really specific about how everything connects together properly. They want solid bonds between those air terminals, all the conductors running through the system, and finally down to the actual grounding points in the earth. Getting this right means the whole lightning protection system works as intended instead of failing when it matters most during a storm.

LPI-175 Certification and the Benefits of Code-Compliant Grounding Components

The LPI-175 standard from the Lightning Protection Institute basically checks if components can stand the test of time and work well within complete system setups. Industrial facilities that install grounding rods certified under this standard tend to save between 30 to 50 percent on maintenance expenses down the road. A look at what happened during lightning strikes across various industries in 2023 backs up these savings claims. What's more, getting that LPI-175 certification means all those parts will fit together nicely with things like surge protectors and bonding jumpers. This compatibility helps cut down dangerous situations where electricity jumps around unexpectedly or creates unsafe voltage differences in the ground itself.

Navigating Regional Differences in Enforcement of UL and NFPA Grounding Requirements

NFPA 780 has become pretty standard throughout most parts of the United States, but don't forget there are still those local building codes that throw in extra rules sometimes. Take coastal communities for instance where they tend to specify stainless steel grounding rods over copper clad ones because salt air just eats away at regular materials so fast. Then again, folks living in areas with lots of rocks might get away with digging a bit less deep (around six to eight feet) if they throw in some chemical electrodes for good measure. The bottom line? Nobody knows better than the people running things on the ground level. Talk to both city officials and independent inspection services first thing when putting together any kind of lightning protection setup.

Best Practices for Grounding Rod Installation and Long-Term Reliability

Proper grounding rod depth, spacing, and interconnection per NFPA 780

Grounding rods should be driven straight down into the earth at least 8 feet deep (that's about 2.4 meters) to reach those stable, damp soil layers that work best for grounding purposes according to NFPA 780 guidelines. When installing multiple rods, make sure they're spaced out properly. The general rule is to keep them at least double their own length apart, so around 16 feet or 4.8 meters between each rod helps avoid any interference issues. For connecting several rods together, it makes sense to go with bare copper wires joined through those special compression fittings instead of regular mechanical clamps. These compression connections create a much better lasting connection that won't loosen over time and maintains that critical low resistance pathway needed for proper grounding performance.

Techniques to minimize ground resistance and enhance system efficiency

When dealing with soil that has high resistivity, adding ground enhancement materials like bentonite clay or conductive concrete can really help boost contact effectiveness. For areas where freezing temperatures are common, driving grounding rods well below ground level helps prevent damage from frost heaving. Many industrial installations find that ring grounding works best, with multiple layers of electrodes forming a protective circle around buildings and equipment. Regular checks on resistance levels are essential too. Most residential setups need readings under 25 ohms while places like data centers often demand much stricter standards, usually below 5 ohms. These measurements matter because they ensure safety and proper functioning of electrical systems across different environments.

Installation considerations for residential vs. commercial lightning protection systems

When setting up grounding systems for homes, it's best practice to position those grounding rods outside the basement walls. Use a single 8 foot long copper bonded rod connected properly to the conductors at roof level. Commercial properties built on asphalt need something different though. Concrete encased electrodes should go into the ground near the building foundations. And don't forget about telecom towers which demand special attention. These require radial grounding arrays consisting of at least ten rods all linked together through exothermic welding techniques. Maintenance is important too so always remember to install clear access wells wherever grounding rods meet soil. This makes future inspections much easier when checking connections down below.

Common grounding rod installation errors and how to avoid them

Never cut grounding rods shorter than eight feet or lay them flat horizontally because doing so cuts down on soil contact by about two thirds. For mixed metal setups where copper meets steel, remember to put those dielectric unions between components to stop galvanic corrosion from eating away at connections over time. If working with chemical backfill material, make sure to tamp it down in sections roughly twelve inches thick each layer to avoid problems when lightning strikes nearby. After installation, always check resistance levels using proper measuring tools. Systems that skip this testing step tend to fail much more often during thunderstorms, with studies suggesting around forty three percent increased risk compared to properly tested installations.

FAQ

What are grounding rods used for in lightning protection systems?

Grounding rods are used in lightning protection systems to channel electrical surges into the Earth's conductive layers, preventing damage to structures and equipment.

Why is copper preferred over aluminum for grounding rods?

Copper is preferred over aluminum because it has better conductivity and corrosion resistance, making it more durable in harsh conditions.

How can soil conditions affect grounding rod effectiveness?

Soil conditions can affect grounding rod effectiveness by influencing soil resistivity, which determines how well electricity flows through the ground.

What are the key standards for grounding system design?

Key standards for grounding system design include NFPA 780 and UL 96A, which guide the materials and installation processes to ensure safety and reliability.

What are common installation errors to avoid?

Common installation errors to avoid include cutting rods too short, failing to check soil resistivity, and not performing resistance tests.

Table of Contents

- Understanding the Role of Grounding Rods in Lightning Protection Systems

- Copper vs. Aluminum Grounding Rods: Corrosion Resistance and Conductivity

- Solid Copper vs. Copper-Clad Steel: Cost, Performance, and Longevity

- Importance of UL-Listed Materials and Quality Certification

- Assessing Soil Conditions to Optimize Grounding Rod Effectiveness

- Ensuring Compliance with Lightning Protection and Grounding Standards

- Best Practices for Grounding Rod Installation and Long-Term Reliability

- FAQ