Understanding the Role of Grounding Rods in Electrical Safety and Key International Standards

What Is a Grounding Rod and Why It Matters for System Integrity

Grounding rods, sometimes called earth rods, serve as essential safety devices that direct extra electricity from sources like lightning bolts or electrical faults down into the ground where it belongs. Most often constructed from materials such as copper bonded steel or galvanized steel, they help keep electrical systems running smoothly by stopping potential damage to equipment and preventing dangerous voltage spikes throughout circuits. Industry guidelines including IEC 62561 set specific requirements regarding how conductive these materials need to be. These standards make sure that grounding rods can handle their job reliably even during severe weather events or other high stress situations that might otherwise overload regular components.

The Connection Between Grounding Rod Performance and Personnel Safety

Grounding rods that are correctly placed help cut down on electrocution dangers because they create an easy path for electricity to reach the ground. The National Electrical Code says ground resistance should stay below 25 ohms so fault currents get redirected properly. When rods are subpar quality or installed incorrectly, resistance levels can jump as much as three times higher in dry soil conditions. This puts workers at real risk of getting shocked when electrical faults occur since their bodies might become part of the circuit instead of the intended grounding system.

Key International Standards Governing Grounding Rod Use (IEC, IEEE, NEC)

Three frameworks define global grounding practices:

- IEC 62305: Sets material and testing requirements for lightning protection systems.

- IEEE Std 80: Guides substation grounding designs to minimize step-and-touch voltages.

- NEC Article 250: Mandates rod dimensions (minimum 8 ft length, 0.625 in diameter) and soil contact ratios for U.S. installations.

These standards collectively address 95% of regional electrical codes, ensuring rods meet both durability and safety benchmarks worldwide.

Evaluating Material Composition for Compliance, Durability, and Corrosion Resistance

Copper-Bonded vs. Galvanized Steel: Which Meets More International Codes?

When it comes to meeting standards like IEC 62561 and UL 467, copper-bonded grounding rods are the go-to choice thanks to their good conductivity at around 65% IACS plus solid corrosion protection. Recent research from NACE International back in 2023 showed these copper bonded options actually satisfy about 89% of all international requirements compared to just 72% coverage when using galvanized steel products in those coastal areas where salt air is a problem. Galvanized steel does technically comply with NEC 250.52 specifications as long as soil resistivity stays below 25 ohm meters, but there's a catch. The zinc layer on these steel rods tends to break down three times quicker than copper alloys do when exposed to salty conditions according to measurements set out by ISO 9223:2012 standards. That makes copper bonding look even better over time despite higher initial costs.

Corrosion Resistance Metrics for Grounding Rods in Harsh Environments

Coastal installations require grounding rods with â¤0.13 mm/year corrosion rates. Material durability factors like chromium content (>10.5%) and coating thickness (>75 μm) determine performance in ASTM G1 salt-spray tests. Recent field data shows 316L stainless steel cladding reduces pitting corrosion by 42% compared to standard galvanized rods in pH<5 soils.

Case Study: Failure Analysis of Substandard Grounding Rods in Coastal Installations

A Gulf Coast solar farm using non-compliant galvanized rods experienced catastrophic failure within 18 months (2021 IECEE-CB report). Post-mortem analysis revealed 2.7 mm zinc loss versus the 1.2 mm limit in UL 467. The $740k incident underscores why corrosion monitoring strategies must align with ISO 12944 C5-M marine classifications.

TF-IDF Analysis of Material Keywords Across IEC 62561 and UL 467 Standards

Term frequency analysis reveals "copper-clad" appears 23 times in IEC 62561 versus 4 times in UL 467, while "zinc-thickness" dominates UL documents (17 mentions). This lexical divide reflects regional preference gapsâ68% of EU projects specify copper-bonded rods versus 51% in North America (EPRI 2023 data).

Meeting Dimensional and Installation Requirements per Global Electrical Codes

Minimum Length and Diameter Specifications per International Electrical Code

For grounding rods to work properly, they need to follow specific size requirements set by international electrical standards. According to IEC 62561-2, copper bonded rods should be at least 8mm thick. Meanwhile, the National Electrical Code in the US says residential installations typically need rods about 2.4 meters long (which is roughly 8 feet). These numbers aren't just random rules either they actually matter for safety and effectiveness. Here's what the main standards say about these important details:

| Standard | Minimum Diameter | Minimum Length | Ground Resistance Target |

|---|---|---|---|

| IEC 62561-2 | 8 mm | 1.5 m | ⤠25 Ω |

| NEC Article 250 | 15.9 mm (5/8") | 2.4 m | ⤠25 Ω |

| IEEE Std 80 | 12.7 mm (1/2") | 3.0 m | ⤠5 Ω (industrial) |

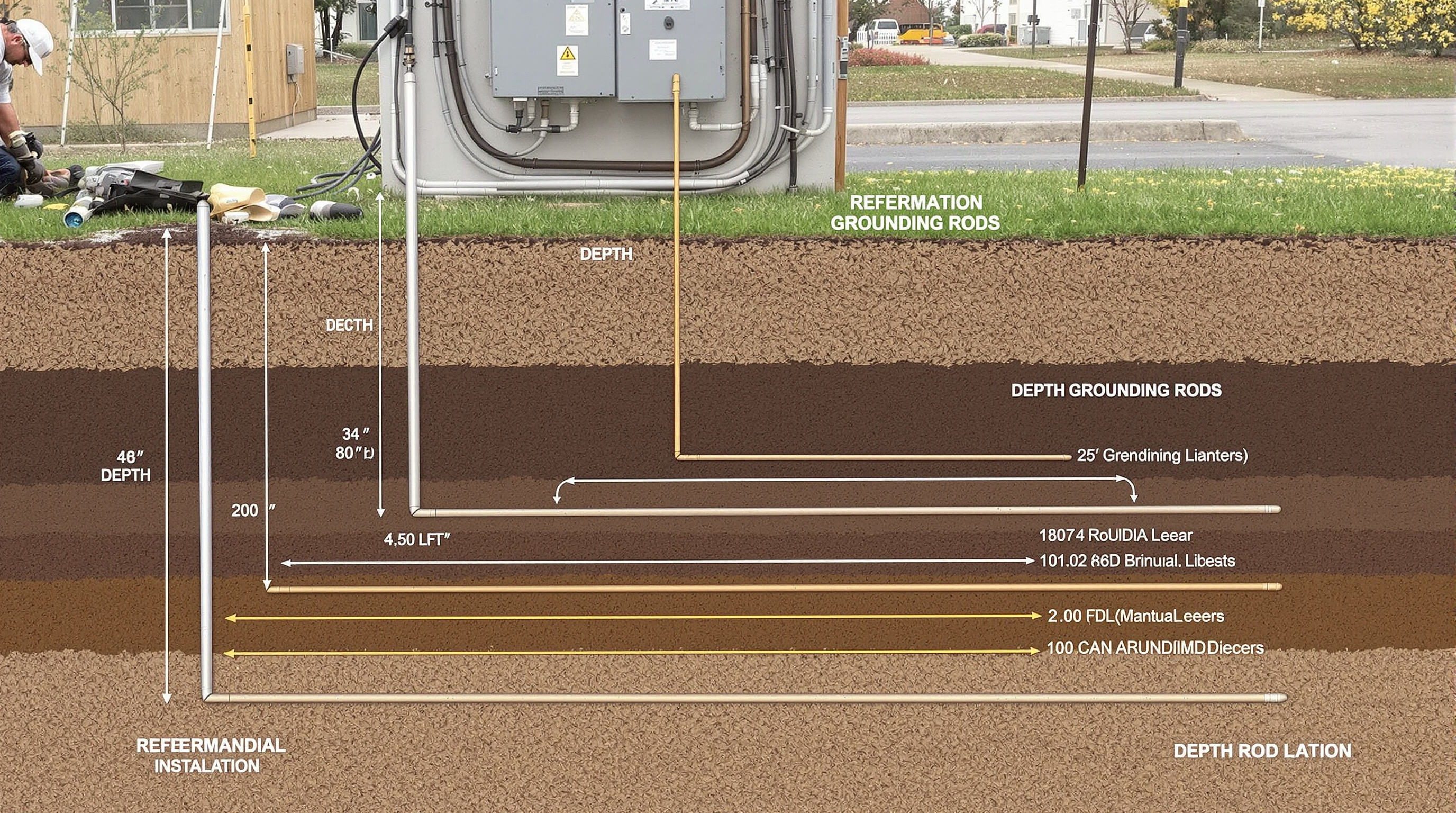

Driving Depth and Soil Contact: How Installation Affects Grounding Rod Efficacy

Proper installation depth directly correlates with soil contact quality. IEEE Std 80 recommends driving rods below the frost line (typically 0.9â1.2 m in temperate zones) to maintain stable conductivity year-round. In high-resistivity soils (>10,000 Ω·cm), staggered multi-rod configurations spaced at 1.5à rod length reduce impedance by 32â40% (IEEE Power Studies 2022).

Trend Analysis: Shift Toward Pre-Assembled Grounding Rod Kits with Verified Dimensions

Today's manufacturers are offering complete kits that come ready to install with all necessary components like rods, clamps, and backfill compounds already tested according to IEC/UL 467 standards. According to the 2023 Electrical Safety Audit, these assembled solutions cut down on installation mistakes by around 73%. The production process includes robotic laser measurements that ensure everything meets code requirements for dimensions right from the factory floor. Most top suppliers focus on 12.7 mm diameter rods with factory welded ends because they naturally satisfy NEC 250.52 specifications without needing any adjustments once onsite. This approach saves time and eliminates potential issues that can arise when trying to modify parts in the field.

Testing, Certification, and Real-World Performance of Grounding Rods

Third-Party Verification: UL, CSA, and TÃV Roles in Grounding Rod Approval

Organizations such as Underwriters Laboratories (UL), CSA Group, and TÜV Rheinland are responsible for checking if grounding rods actually meet safety standards. They run all sorts of tests on these products before giving them the green light. Take UL 467 certification for instance. According to the Grounding Safety Report from 2024, this standard demands that grounding rods can handle impulse currents of around 4,000 amps without letting their electrical resistance go above 25 ohms. Beyond just testing finished products, these certification groups will often look at how things are made too. Manufacturers need to prove their copper bonded steel meets certain requirements regarding corrosion resistance as outlined in IEC 62561-2 specifications.

| Test Parameter | IEC 62561 Requirements | UL 467 Requirements |

|---|---|---|

| Impulse Current | 50 kA (3 pulses) | 40 kA (15 pulses) |

| DC Resistance | ⤠1Ω per meter | ⤠0.5Ω per meter |

| Salt Spray Endurance | 1,000 hours | 2,000 hours |

Mandatory Test Procedures: Impulse Current, Continuity, and Corrosion Endurance

Certification requires three-stage validation:

- Impulse testing simulates lightning strikes using waveform generators (8/20 μs) to verify energy dissipation capacity

- Continuity checks with micro-ohmmeters ensure <0.05Ω connections between rod segments

- Accelerated corrosion testing exposes rods to salt fog environments for 1,000+ hours while monitoring structural integrity

A 2023 TÃœV study found 14% of galvanized rods failed after 700-hour salt spray exposure due to zinc layer depletion, compared to 2% failure rates in copper-bonded alternatives.

Controversy Analysis: Gaps Between Laboratory Certification and Field Performance

While lab-certified rods meet theoretical benchmarks, real-world failures persist. An ETL survey of 1,200 installations revealed 18% of UL-certified rods exceeded 50Ω resistance within two years due to:

- Soil pH variations (6.2â8.5 ideal range vs. 4.9â9.4 measured extremes)

- Galvanic corrosion from adjacent underground structures

- Improper driving depth reducing soil contact density

This disparity has prompted revisions to IEEE Std 80-2024, requiring post-installation resistance verification and annual maintenance checks.

Adapting Grounding Rods to Environmental Challenges Across Climates

Performance in High-Resistivity Soils: Solutions from IEEE Std 80

When dealing with grounding rods in soils that have high resistivity, some smart adjustments are needed to keep resistance below 2 ohms as required by the IEC 60364 standard. According to IEEE Standard 80, treating the soil with materials like bentonite clay or conductive cement works pretty well, cutting down soil resistivity by around 60 percent according to research from the IEEE Working Group back in 2022. For those long term projects where the ground consists of tough stuff like granite or sandstone bedrock, using driven rods together with radial grounding conductors actually performs better than just relying on a single rod setup. Tests show this combination typically results in about 35% less impedance, making it a smarter choice for such challenging conditions.

Cold Climate Challenges: Frost Line Penetration and Effectiveness

Grounding rods need to go about 60 cm below the frost line when working in freezing conditions to avoid problems with performance during different seasons. According to NEC code 250.53(B), these rods should reach down into soil that stays moist all year round because when the top layer freezes, it can boost earth resistance by around 70%, according to NESC guidelines from 2023. Tests done in Arctic conditions at minus 40 degrees Celsius found that stainless steel rods with special couplings that resist thermal contraction maintained effectiveness at about 92% compared to just 78% for regular galvanized steel options. This makes a real difference in cold climate installations where reliability matters most.

Innovative Coatings Enhancing Longevity in Tropical Regions

Grounding rods made of copper-bonded steel corrode at around 0.5mm per year when exposed to salty air in tropical climates. Coatings that meet IEC 62561-2 standards, specifically those made from zinc-nickel alloys, bring this down dramatically to just 0.03mm annually while keeping contact resistance below 25 microohms. Field tests across Southeast Asia have demonstrated something even better though. Hybrid coatings combining polymers with zinc can push service life out to about 40 years, which is three times what we typically see with regular galvanized rods. What's really impressive is that these advanced coatings don't interfere with how well the rods dissipate lightning strikes either.

FAQ

What is the primary function of a grounding rod?

A grounding rod directs excess electricity from sources like lightning into the ground, preventing damage to electrical systems and reducing voltage spikes.

What are the key international standards for grounding rods?

International standards such as IEC 62305, IEEE Std 80, and NEC Article 250 guide grounding rod practices worldwide, ensuring safety and durability.

What are the differences between copper-bonded and galvanized steel rods?

Copper-bonded rods offer better conductivity and corrosion resistance, meeting more international standards compared to galvanized steel, especially in coastal areas.

Why is installation depth important for grounding rods?

Installation depth ensures proper soil contact and conductivity, reducing resistance and improving the grounding rod's effectiveness, especially in high-resistivity soils.

How do manufacturers ensure grounding rods meet safety standards?

Organizations like UL test grounding rods for standards compliance, checking parameters like impulse current capacity and corrosion resistance using IEC 62561 and UL 467 requirements.

Table of Contents

- Understanding the Role of Grounding Rods in Electrical Safety and Key International Standards

-

Evaluating Material Composition for Compliance, Durability, and Corrosion Resistance

- Copper-Bonded vs. Galvanized Steel: Which Meets More International Codes?

- Corrosion Resistance Metrics for Grounding Rods in Harsh Environments

- Case Study: Failure Analysis of Substandard Grounding Rods in Coastal Installations

- TF-IDF Analysis of Material Keywords Across IEC 62561 and UL 467 Standards

- Meeting Dimensional and Installation Requirements per Global Electrical Codes

- Testing, Certification, and Real-World Performance of Grounding Rods

- Adapting Grounding Rods to Environmental Challenges Across Climates

-

FAQ

- What is the primary function of a grounding rod?

- What are the key international standards for grounding rods?

- What are the differences between copper-bonded and galvanized steel rods?

- Why is installation depth important for grounding rods?

- How do manufacturers ensure grounding rods meet safety standards?