Understanding Grounding Rod Conductivity and System Safety

What Is Grounding Rod Conductivity and Why It Matters

The conductivity of grounding rods basically tells us how well they can move electricity from whatever source down into the ground. When rods have good conductivity, they get rid of electrical faults, lightning hits, and static build-up much faster. This makes workplaces safer for people working around them and helps protect expensive equipment from damage over time. Take copper bonded rods for instance these typically conduct electricity about five times better than regular galvanized steel options. That's why many industries and telecom companies prefer them, especially when dealing with different types of soil across various installation sites. The varying soil composition means one size doesn't fit all when it comes to grounding solutions.

The Role of Electrical Conductivity in Preventing System Failures

Getting the grounding path resistance down below 25 ohms really matters because it stops those dangerous voltage spikes that could otherwise spark fires, wreck equipment, or even electrocute someone. The International Electrical Testing Association did some work on this back in 2023 and found something pretty striking: systems that hit that resistance target had almost nine out of ten fewer arc faults happening. When the conductivity is right, the whole electrical system handles those sudden power surges better too. Transformers don't get fried as often, and all those delicate electronic components stand a much better chance of surviving what would otherwise be damaging voltage fluctuations.

Common Misconceptions About Pre-Installation Testing of Grounding Rods

-

Myth: “All rods perform equally in different soils.”

Truth: Soil resistivity varies with moisture and mineral content, necessitating site-specific testing for reliable performance. -

Myth: “Visual inspections suffice for conductivity assurance.”

Truth: Internal corrosion or manufacturing defects are often invisible without electrical testing using tools like multimeters or the four-point Wenner method. -

Myth: “Pre-testing delays projects unnecessarily.”

Truth: Early testing prevents costly retrofits and regulatory fines due to noncompliance, ultimately saving time and resources.

Key Factors Affecting Grounding Rod Conductivity

Soil Resistivity: The Foundation of Effective Grounding Performance

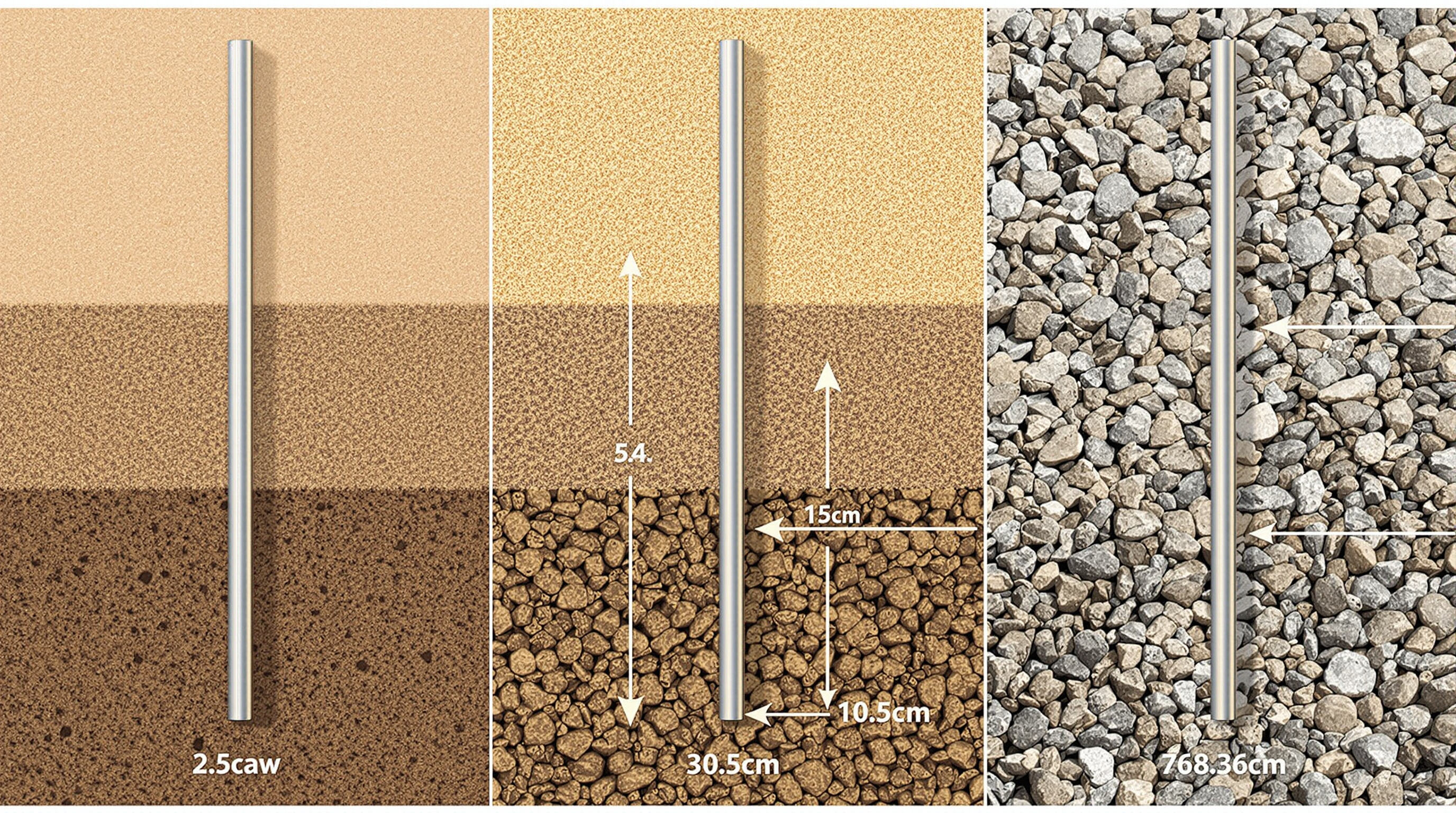

Soil resistivity, measured in ohm-centimeters (Ω·cm), is the primary determinant of a grounding rod’s effectiveness. Variations in soil type significantly influence resistance levels:

| Soil Type | Typical Resistivity (Ω·cm) | Performance Implications |

|---|---|---|

| Clay | 2,000–5,000 | Optimal conductivity |

| Sand | 20,000–100,000 | Requires deeper or multiple rods |

| Rocky/Gravel | 50,000–500,000 | Often needs chemical treatment |

When soil gets really dry, meaning it has lost more than 10 percent of its moisture content, this can actually make things more resistant electrically by as much as 80 percent according to some recent research from IEEE in 2023. Before installing anything though, doing some basic tests on the ground itself is pretty important. The four point Wenner technique works well for figuring out where best to place grounding rods and how deep they need to go. Clay tends to hold onto water better so sometimes just putting down an eight foot rod will work fine there. But when dealing with sandier ground conditions, folks usually end up needing longer rods around twelve feet long or even multiple ones placed about six to eight feet away from each other depending on what exactly needs grounding.

Environmental Influences: Moisture, Temperature, and Soil Composition

Environmental conditions play a critical role in grounding efficiency:

- Moisture: Enhances conductivity by dissolving minerals but becomes ineffective if the water table drops below rod depth.

- Temperature: Frozen soils (≤0°C) increase resistivity by 5–10 times; high temperatures (>35°C) reduce moisture retention, degrading performance.

- Composition: Saline soils improve conductivity but accelerate corrosion, while compacted or rocky soils limit contact between rod and earth.

These variables cause resistance fluctuations of 30–70% across seasons and locations, emphasizing the need for dynamic assessment and design adjustments.

Applying Ohm’s Law to Ground Resistance Measurement Techniques

Ohm’s Law (V = IR) forms the basis of ground resistance evaluation, enabling technicians to relate voltage, current, and resistance during field tests. This principle supports:

- Calculating required rod length based on soil data.

- Validating results in fall-of-potential tests.

- Identifying anomalies such as unexpected spikes (>50Ω in residential systems).

For example, injecting 1A into a rod in 10,000 Ω·cm soil with a measured 25V drop indicates 25Ω resistance—meeting standard thresholds but warranting monitoring in fluctuating environments.

Standard and Advanced Testing Methods for Grounding Rods

Preliminary Checks Using a Multimeter for Grounding Rod Conductivity

Most techs start their inspection with a good old multimeter to test for basic continuity and spot those big problems such as broken wires or serious corrosion issues. When checking resistance between the grounding rod and some temporary electrode, this simple test helps catch conductive failures pretty quickly. The numbers matter too industry standards generally look for readings under 25 ohms in homes and around 5 ohms for bigger industrial installations. It's worth noting though that while this gives a quick safety heads up, it doesn't tell the whole story. After getting these preliminary results, experienced technicians know when to dig deeper with more sophisticated diagnostic tools based on what they see during this first pass.

Four-Point Wenner Method for Accurate Soil and Rod Assessment

Among all the available techniques, the four point Wenner approach still stands out as the most reliable way to measure soil resistivity. The setup involves placing electrodes at regular intervals usually between 10 to 30 meters apart. Current gets injected into the ground while measuring how much voltage drops occurs across these points, which helps determine resistivity values at different soil depths. Research indicates this method cuts down on measurement mistakes by somewhere around 60 to 80 percent when compared to basic alternatives. That makes a big difference when engineers need to design proper grounding systems, especially where soil conditions change frequently or are inherently unstable.

Two-Point Contact Resistance Testing: When to Use and Limitations

The method basically checks how much resistance exists between the grounding rod and some established earth reference point, often something like a metal water pipe running through the building. This comes in handy when trying to upgrade older systems because sticking extra probes into the ground just isn't practical in many cases. But there's a catch worth mentioning here. The existing wiring in buildings sometimes creates alternative grounding paths that throw off measurements, making numbers look artificially high by around 15 to maybe even 30 percent. That kind of error margin means technicians need to approach this technique with care. For really important applications where accuracy matters most, always double check results against proper three or four point testing procedures first before making any final decisions based on these readings alone.

Clamp-On Ground Testers and Digital Earth Resistance Testers Compared

| Feature | Clamp-On Testers | Digital Earth Testers |

|---|---|---|

| Accuracy | ±10% (ideal for multi-rod systems) | ±2% (suitable for standalone rods) |

| Speed | 2–3 minutes per test | 10–15 minutes with probes |

| Best For | Maintenance checks | Pre-installation verification |

Clamp-on testers excel in live environments and save time but are unreliable for single-electrode systems. Digital testers provide laboratory-grade precision but require more setup and are best suited for commissioning new installations.

Modern Tools: GPS, Data Logging, and Environmental Sensors in Testing

Modern testing equipment now comes with built-in GPS for marking where measurements are taken, plus Bluetooth data loggers that create compliance reports without any manual input needed. A few models even have sensors that check soil moisture levels on the spot, adjusting resistance readings according to what's actually happening around them. Research from last year showed these kinds of adjustments can boost accuracy by about 22% when working with grounding materials. All these tech upgrades help people make better decisions in the field while bringing old school methods into line with what today's smart grids really need to function properly.

Real-World Applications and Case Studies in Pre-Installation Testing

Telecom Tower Grounding Failure Due to Untested Grounding Rods

A telecom tower along the coast fell down last year following a lightning strike because nobody had ever tested those grounding rods. When engineers looked into what went wrong, they found that just 28 percent of the needed conductivity was left in the system. Saltwater from the nearby ocean had corroded everything over time. The whole mess ended up costing around $410k worth of damaged equipment and knocked out services for three full days straight according to some research published in the International Journal of Electrical Safety. This incident really shows how important it is to follow ASTM F855 guidelines which require checking conductivity before putting any infrastructure into place where there's a risk of corrosion happening naturally.

Ensuring Compliance in Industrial Plants with Proper Earth Rod Testing

Industrial facilities that adopted a three-stage verification process reduced ground-related faults by 63% (NFPA 2022 Report):

- Soil resistivity mapping via the four-point Wenner method

- Rod-to-earth validation using clamp-on testers

- Annual retesting with IoT-enabled sensors

This approach meets IEEE 80 standards and helps avoid OSHA penalties, which average $156,000 per electrical safety violation.

Verifying Conductivity in Residential Lightning Protection Systems

Homeowners in lightning-prone areas enhance safety by ensuring grounding rod conductivity exceeds 90% of manufacturer specifications. The Lightning Protection Institute reports properly tested systems reduce fire risk by 81% compared to unverified installations. Essential steps include:

- Multimeter checks confirming rod integrity (≥ 5.0 S/m conductivity)

- Soil pH analysis around installation zones

- Fall-of-potential testing to verify total system resistance below 25Ω

These examples demonstrate that thorough pre-installation testing significantly improves safety outcomes across residential, industrial, and telecommunications sectors.

Future Trends in Ground Resistance Measurement and Smart Grounding Systems

IoT Integration for Real-Time Monitoring of Electrical Conductivity of Earth Rods

Grounding systems connected to IoT technology have started incorporating wireless sensors for ongoing checks of soil resistivity and how well the grounding rods conduct electricity. Facilities that implement this kind of real time monitoring see around half again fewer electrical problems than places still doing old fashioned manual tests every few months. The systems keep tabs on important factors like moisture levels in the air, which becomes really important when humidity drops under 20%, plus they watch for changes in ground potential. When measurements go beyond what's considered safe according to the latest IEEE guidelines from 2023, the system sends out warnings so technicians can investigate before anything goes wrong.

Regulatory Shifts Toward Mandatory Pre-Installation Grounding Rod Testing

After the latest changes to NFPA 780-2024 regulations, 46 states across America have started requiring independent checks on how well grounding rods conduct electricity for all commercial construction work. The rules specifically call for what's known as the four point Wenner method when testing these rods, which basically means making sure they don't show more than 25 ohms of resistance in normal soil conditions. Why this matters became clear after a FEMA report came out in 2023 revealing that nearly one third of lightning damage incidents at factories and warehouses happened because nobody had actually tested their grounding systems first. These findings really highlighted why having consistent, scientifically backed testing procedures has become so important for safety standards.

FAQ

What is the purpose of grounding rod conductivity?

Grounding rod conductivity is crucial for effectively dissipating electrical faults, lightning strikes, and static build-up into the ground, enhancing safety and protecting equipment.

Why do copper bonded rods perform better than galvanized steel?

Copper bonded rods typically conduct electricity about five times better than regular galvanized steel options, making them preferable for industries dealing with varied soil types.

What impact does soil resistivity have on grounding rod effectiveness?

Soil resistivity influences grounding performance significantly, where low resistivity (e.g., clay) provides optimal conductivity, while high resistivity (e.g., sand) may require additional rods or chemical treatments.

How do environmental factors affect grounding efficiency?

Environmental factors like moisture, temperature, and soil composition can cause resistance fluctuations in grounding systems, impacting safety and efficiency.

What are some standard methods for testing grounding rod conductivity?

Standard methods include multimeter checks for preliminary testing, the four-point Wenner method for soil resistivity, and clamp-on and digital earth resistance testers for accurate assessments.

Table of Contents

- Understanding Grounding Rod Conductivity and System Safety

- Key Factors Affecting Grounding Rod Conductivity

-

Standard and Advanced Testing Methods for Grounding Rods

- Preliminary Checks Using a Multimeter for Grounding Rod Conductivity

- Four-Point Wenner Method for Accurate Soil and Rod Assessment

- Two-Point Contact Resistance Testing: When to Use and Limitations

- Clamp-On Ground Testers and Digital Earth Resistance Testers Compared

- Modern Tools: GPS, Data Logging, and Environmental Sensors in Testing

- Real-World Applications and Case Studies in Pre-Installation Testing

- Future Trends in Ground Resistance Measurement and Smart Grounding Systems

-

FAQ

- What is the purpose of grounding rod conductivity?

- Why do copper bonded rods perform better than galvanized steel?

- What impact does soil resistivity have on grounding rod effectiveness?

- How do environmental factors affect grounding efficiency?

- What are some standard methods for testing grounding rod conductivity?